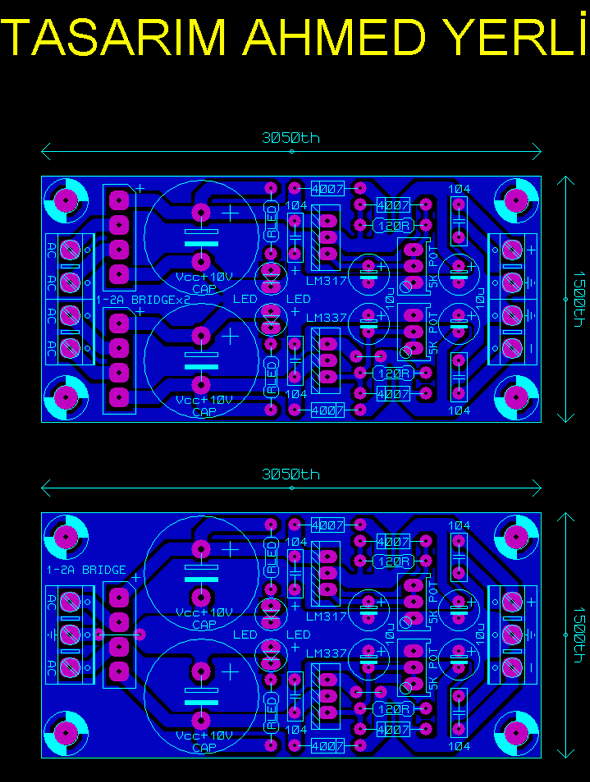

Power Supply Using Lm317 And Lm337 Together

Variable Power Supply using LM317 The capacitance C3 bypassing the ADJUST pin to ground will improve the ripple rejection capability while the diodes are used to protect the regulator from excess flowing through it if a battery or any other voltage source is connected across the output terminals of the regulator.

A is a must for every electrical and electronic work bench and it’s available in a variety of shapes and sizes in the market and also in the form of schematics to us.These may be built using discrete components like transistors, resistors etc. Or incorporating a single chip for the active functions.

Though the shown design is the simplest one and therefore includes only a voltage control feature, a current control feature can also be included with the IC. Adding a Current Control FeatureThe figure above shows, how the IC LM317 can be effectively used for producing variable voltages and currents, as desired by the user. The 5K pot is used for adjusting the voltage, whereas the 1 Ohm current sensing resistor is selected appropriately to acquire the desired current limit. Enhancing with High Current Output FacilityThe IC can be further enhanced for producing currents higher than its rated values. The diagram below shows how the IC 317 can be used for producing more than 3 amps of current.

LM317 Variable Voltage, Current RegulatorOur versatile IC LM317/338/396 may be used as an adjustable voltage and current regulator through simple configurations.The idea was built and tested by one of the avid readers of this blog Mr. Steven Chiverton and used for driving special laser diodes which are known to have stringent operating specifications, and could be driven only through specialized driver circuits.The discussed LM317 configuration is so accurate that it becomes ideally suitable for all such specialist current and voltage regulated applications. Circuit OperationReferring to the shown circuit diagram, the configuration looks pretty straightforward, two LM317 IC s can be seen, one configured in its standard voltage regulator mode and the other in a current control mode.To be precise the upper LM317 forms the current regulator stage while the lower acts like a voltage controller stage.The input supply source is connected across the Vin and ground of the upper current regulator circuit, the output from this stage goes to the input of the lower LM317 variable voltage regulator stage. Basically both the stages are connected in series for implementing a complete foolproof voltage and current regulation for the connected load which is a laser diode in the present case.R2 is selected to acquire a range of around 1.25A max current limit, the minimum allowable being 5mA when the full 250 ohms is set in the path, meaning the current to the laser may be set as desired, anywhere between 5mA to 1 amp. Calculating the Output VoltageThe output voltage of a LM317 power supply circuit could be determined with the following formula:VO = VREF (1 + R2 / R1) + (IADJ × R2)where is = VREF = 1.25Current ADJ is usually around 50 µA and therefore too negligible in most applications.

You can ignore this. Calculating Current LimitThe above is calculated by using the following formula:R = 1.25/max allowable currentThe current controlled voltage acquired from the upper stage is next applied to the lower LM317 voltage regulator circuit, which enables the desired voltage to be set anywhere from 1.25V to 30V, here the max range being 9V since the source is a 9V battery. This is achieved by adjusting R4.The discussed circuit is assigned to handle not more than 1.5amps, if higher current is required, both the ICs may be replaced with LM338 for obtaining a max 5amp current or LM396 for a max of 10amp current.The following lovely pictures were sent by Mr. Steven Chiverton, after the circuit was built and verified successfully by him. Prototype Images Upgrading LM317 with Push Button Voltage ControlSo far we have learned how to configure an LM317 for producing adjustable output using a pot, now let's understand how push buttons may be used for enabling digitally controlled voltage selection. Sir i’m refering to this first circuit l.e variable power supply circuit using lm317 the place you indicate 28v as input, how can i modified it to 12volt. Next query is that i build 1kva inverter but my problem is that i don’t have the money to purchase 12v 100ah battery, but according to the information i gather it said that automobile battery is meant for starting of vehicle and not for inverter.

It also stated that inverter battery is deep cycle battery, now can you explain reason why automobile battery is not meant for inverter, because i have 75ah automobile battery at my disposal. Sir i will be waiting for your response. I'm sorry, not a timer, i mean some controller that's designed for smps, like pwm.When using a linear regulator like LM317 I can feel a lot of heat on the heatsinks both from the ic and power transistors, and I believe that's a wasted power.I googled the formula of the wasted heat, (Vin – Vout) x Amps.eg. (18V – 6V) x 3A = 36Watts of wasted heat.So if you could please teach me how I can get high efficiency by using alternative other than linear regulator.

Building a complete smps, with ferrite core, is too hard for me. Thank you Mr. Swagatam, a new lesson learned today.Anyway I'd like to stock up common diodes at home, like 1n4001. Most people recommend the 1n4007-the highest voltage rating ones. With their particularly equal price, why do the manufactuter still make the lower ones? When I go to the retailer and ask for 1n4001 they give me 1n4007 instead, and saying 'its the same'. I dont think it's true, a 'marking' means 'something', right.

And what about 1n5819 Schottky diodes, should I stock them up for my everyday electronics? Can they be used as the substitute for the 1n400x series?Thank you in advance Mr. Swagatam for your advice.

Hi sir,I came across your work on “Bicycle Dynamo Battery Charger Circuit” in Homemade circuit design blog. It was really informative. I would like to ask something regarding that article. I am working on a hexapedal robot with battery switching mechanism. Once the primary battery gets beyond a preset voltage, secondary battery will power up the robot’s system. My concern is not regarding the switching circuit. Together with this, I am working on energy generation by attaching a generator to each motor.

The current generated is intended to be used to recharge 30C 11.1V 2200mAh 3 cell LiPo battery. I am aware that the circuit mentioned in “Bicycle Dynamo Battery Charger Circuit” will not be useful for my purpose. Can you give me any other option pertaining my issue. I just need to know on how to modify the circuit to make it LiPo compatible.

Thanks, looking forward for a reply.Regards,Arun Prashan. Hi SwagatamI need your help to get rid of the frustration I am experiencing with my first LM317 circuit.As the configuration is quite simple, I soldered the components on PCB straightaway. The value of the resistor was selected based on the value of the POT and the required output voltage (30V). The step down transformer is about 500mAInitially the 30V-analog voltmeter would show more than 30V.

When I adjusted the POT, I noticed some spark or flash inside the POT. And then the output remains within 28V-32V.

The current consumption of the load is hardly 100mA.I assembled fresh components on a breadboard but same results. I checked the circuit on the simulator, it works perfectly.so where am I wrong???. Hi Abu-Hafss,R1 could be 240 ohms or a 120 ohms, it won't make any difference as long the pot is selected for satisfying both the values in other words a 10K pot would be just enough.so R1 is not so crucial.There's hardly anything one can suggest regarding the troubleshooting of the first circuit, because it's as simple as can be.Only two things which you probably know that could be causing the problems are, incorrect pin connections, or faulty (duplicate) devices. There's nothing else that could blow these devices of as these devices have a thorough and very robust internal protection circuitry. Hello sir, I want to ask that for the above circuit which dynamo would be suitable as we want to charge our laptop from dynamo by using it in our bike wheel. And to charge a laptop e will require atleast 24v and from dynamo I don't know this much power can be generated or not and if it can be done then which dynamo will be used as there are different types of dynamo.so should we use a d.c. Motor as an input source or dynamo can work here.

Lm317 Circuits Projects

And please specify the ratings and type of d.c. Motor or dynamo.Thank you.